3D printed products: unlimited possibilities from creativity to reality

Introduction

3D printing technology has made great progress in recent years and is changing the way many industries produce. From prototyping to end products, 3D printed products are being adopted by more and more companies and individuals with their high precision, flexibility and cost-effectiveness. Whether it is personalized accessories, industrial parts, or medical implants, 3D printing is helping us turn imagination into reality. This article will explore the production process, application areas, advantages and future development trends of 3D printed products.

1. Production process of 3D printed products

The production process of 3D printed products can be divided into several key steps, each of which affects the quality and performance of the final product.

1.1 Design and modeling

The first step in 3D printing is to create a digital model, usually using CAD (computer-aided design) software such as SolidWorks, Fusion 360 or Blender. Designers can create complex geometric structures according to their needs and optimize the shape and strength of the product.

1.2 Slicing Process

After completing the 3D model, you need to use slicing software (such as Cura, PrusaSlicer or Simplify3D) to convert the model into G code. This step breaks down the 3D model into layers of slices and generates paths for the printer to control the movement of the nozzle and the way the material is deposited.

1.3 Material Selection

Different application scenarios require different printing materials. Common 3D printing materials include:

PLA (polylactic acid): environmentally friendly, easy to print, suitable for making display models, toys, etc.

ABS (acrylonitrile butadiene styrene): heat-resistant, strong, suitable for functional parts.

TPU (thermoplastic polyurethane): flexible material, suitable for products that require elasticity such as soles and protective shells.

Metal powder (such as titanium, aluminum, stainless steel): used in aerospace, medical and industrial parts manufacturing.

Resin: used in light-curing 3D printing technology, suitable for high-precision printing, such as dental models, jewelry making, etc.

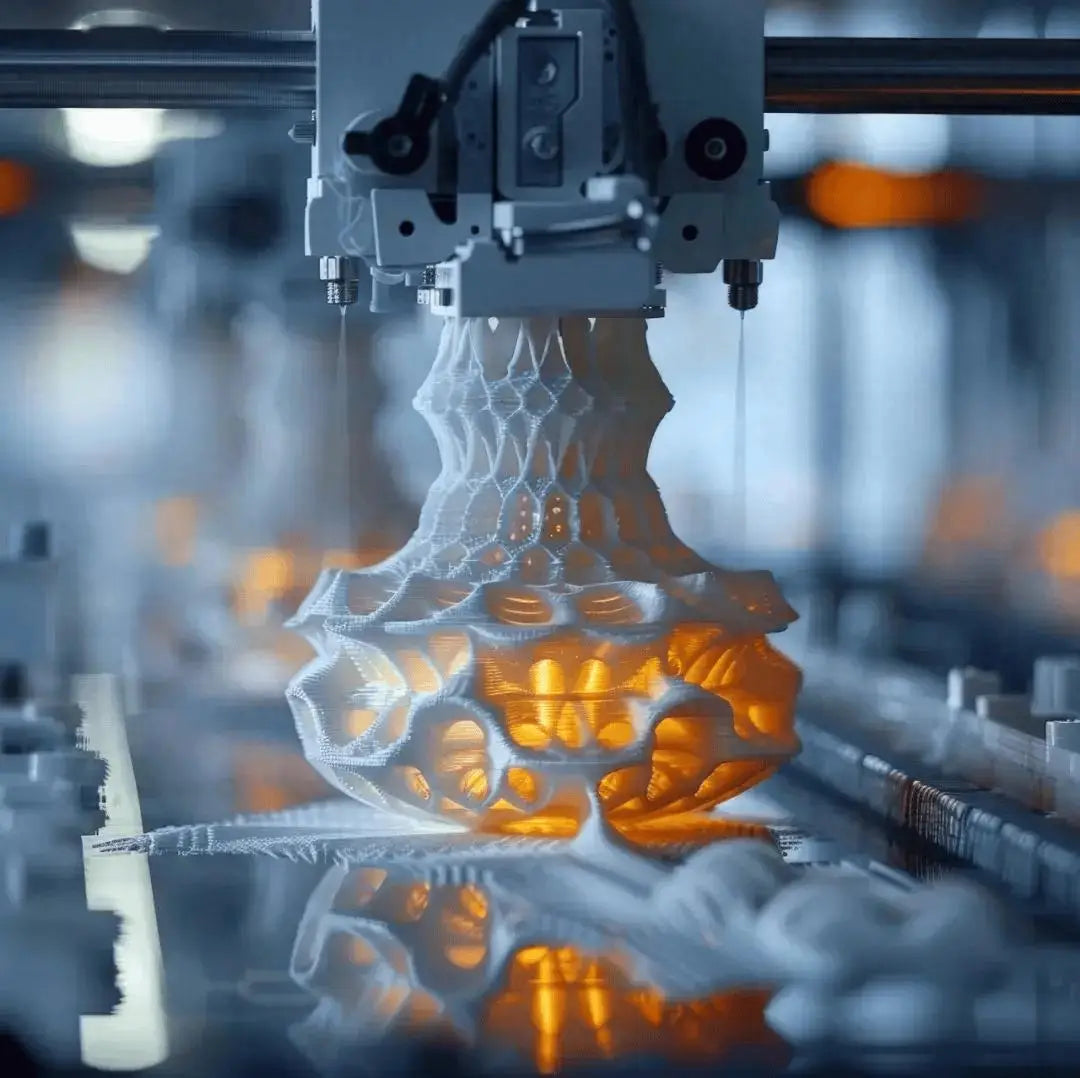

1.4 3D printing process

The printer accumulates materials layer by layer according to the G code and gradually builds a complete object. Printing time depends on the size of the model, the resolution and the material used. Small parts may only take a few hours, while complex industrial parts may take several days.

1.5 Post-processing

Many 3D printed products need post-processing after printing to improve surface quality and functionality. Common post-processing methods include:

Removing support: The support structure of FDM printing needs to be removed manually or dissolved with solvents.

Grinding and polishing: Improve surface smoothness, especially for resin prints.

Painting and coloring: Enhance aesthetics and make the product more commercially valuable.

Heat treatment or chemical treatment: Improve strength and durability, such as sintering of metal prints.

2. Application areas of 3D printed products

The flexibility of 3D printing technology has made it widely used in many industries.

2.1 Medical and health

3D printing is increasingly used in the medical industry. From personalized prostheses and orthotics to bioprinted human tissues, 3D printing is revolutionizing the medical field. For example, 3D printed dental models can help dentists make crowns and braces more accurately, while 3D printed implants can be customized to the patient's bone structure.

2.2 Industrial Manufacturing

Many companies use 3D printing technology to make prototypes to accelerate product development. 3D printing can quickly manufacture parts of complex structures without expensive molds. For example, the automotive and aerospace fields use 3D printing to produce lightweight structural parts to reduce fuel consumption and improve performance.

2.3 Architecture and Engineering

The construction industry has begun to use 3D printing to make architectural models and even directly 3D print houses. 3D printed building materials (such as concrete) can significantly shorten construction time and reduce construction costs. For example, Dubai has built the world's largest 3D printed office building, which shows that 3D printing has great potential in the construction industry.

2.4 Personal consumer goods and customized products

The customization capabilities of 3D printing make it ideal for the production of jewelry, toys and fashion accessories. For example, many people use 3D printers to make personalized mobile phone cases, earrings, sculptures and other unique products. In addition, some brands have begun to offer 3D printed shoes and clothing, allowing consumers to customize products according to their personal preferences.

2.5 Education and scientific research

The application of 3D printing in the field of education can help students understand complex concepts more intuitively. For example, biology students can print anatomical models, and engineering students can print prototypes of mechanical parts. In addition, 3D printing is also commonly used in scientific research to manufacture experimental equipment and simulation models.

3. Advantages of 3D printed finished products

Compared with traditional manufacturing methods, 3D printing has the following advantages:

Customized production: Each product can be customized according to demand without the need for mold opening, which is particularly suitable for the medical and personalized consumer goods fields.

Reduced costs: For small batch production, 3D printing can reduce material waste and reduce manufacturing costs.

Manufacturing of complex structures: 3D printing can easily realize complex geometric structures that are difficult to complete with traditional processing, such as lightweight support structures, hollow structures, etc.

Fast iteration: During product development, different designs can be quickly tested to shorten the development cycle.

Material diversity: A variety of materials such as plastics, metals, ceramics, and resins can be used to meet different needs.

4. Future Trends

With the continuous advancement of technology, 3D printing is developing towards more intelligent, efficient and multifunctional.

Faster printing speed: The new generation of 3D printers is improving printing efficiency and making large-scale production possible.

Bioprinting breakthrough: Scientists are studying 3D printing of human organs to meet future transplant needs.

Environmental protection and sustainability: Use degradable materials and recycled printing materials to reduce environmental impact.

Large-scale production applications: From single prototype manufacturing to mass production, 3D printing is gradually becoming a mainstream way of industrial manufacturing.

Conclusion

3D printed products have penetrated into multiple industries and are changing the future of manufacturing. From medical, industrial to personalized consumer products, 3D printing provides unlimited possibilities with its unique advantages. With the continuous advancement of technology, we can expect 3D printing to create breakthroughs in more fields and bring more convenience to production and life. If you are interested in 3D printing, you might as well experience this technology yourself and explore the unlimited possibilities from creativity to reality!