3D Printing Material Selection Guide: Common Types, Characteristics and Application Scenarios

Introduction

In the world of 3D printing, choosing the right printing material is crucial. Different materials determine the strength, flexibility, high temperature resistance, environmental friendliness and application scenarios of the finished product. Whether it is used for industrial manufacturing, medical devices, architectural design, or personal DIY, understanding the characteristics and applicable scope of various 3D printing materials can help you optimize the printing effect and improve the success rate of printing.

This article will introduce the common types of 3D printing materials in detail, analyze their advantages and disadvantages, applicable scenarios and purchase suggestions, and help you make a wise choice.

1. Main classification of 3D printing materials

3D printing materials are mainly divided into the following categories:

Thermoplastics (commonly used in FDM): PLA, ABS, PETG, TPU, etc.

Photosensitive resins (commonly used in SLA/DLP): standard resins, high temperature resistant resins, flexible resins, biocompatible resins, etc.

Metal powders (commonly used in SLS/SLM/DMLS): stainless steel, titanium alloy, aluminum alloy, copper, etc.

Ceramics and concrete (architectural 3D printing): used for architecture and artwork manufacturing.

Next, we will introduce the characteristics and applicable scenarios of these materials respectively.

2. Common materials for FDM (fused deposition modeling)

FDM 3D printers mainly use thermoplastics, which are heated and melted in the form of wires and stacked layer by layer. The following are several common FDM materials:

2.1 PLA (polylactic acid) – best for beginners

✔ Advantages:

Easy to print, not easy to warp, suitable for beginners.

Degradable, environmentally friendly material.

Suitable for printing decorations, prototypes and concept models.

❌ Disadvantages:

Strong brittleness, poor heat resistance (deformation at about 60°C).

Not suitable for functional parts.

🔹 Application scenarios:

Toys, decorations, teaching models, non-load-bearing structural parts.

2.2 ABS (acrylonitrile-butadiene-styrene) – high strength, heat resistance

✔ Advantages:

More impact-resistant and high-temperature-resistant (up to 100°C).

The surface can be treated with acetone to make it smoother.

Suitable for mechanical parts, housings, etc.

❌ Disadvantages:

It is easy to warp when printing, and requires a heated bed or a closed printer.

Produces a pungent smell when printing.

🔹 Application scenarios:

Industrial parts, electronic housings, tool handles, mechanical parts.

2.3 PETG (Polyethylene Terephthalate) – A compromise between PLA and ABS

✔ Advantages:

It has the easy printability of PLA and the toughness of ABS.

Water-resistant and chemical-resistant, suitable for outdoor use.

More heat-resistant than PLA (about 70~80°C).

❌ Disadvantages:

Sensitive to humidity, moisture-proof when stored.

Strong adhesion, may clog the nozzle.

🔹 Application scenarios:

Food containers, beverage bottles, industrial parts, outdoor products.

2.4 TPU (Thermoplastic Polyurethane) – Flexible, Elastic Material

✔ Advantages:

High flexibility, can be used to make elastic parts.

Wear-resistant and chemical-resistant.

Can be used for 3D printing soles, mobile phone cases, etc.

❌ Disadvantages:

Slow printing speed, high requirements for the printer.

Requires a direct drive extruder (Direct Drive), not suitable for Bowden system.

🔹 Application scenarios:

Mobile phone cases, soles, shock-absorbing parts, medical orthotics.

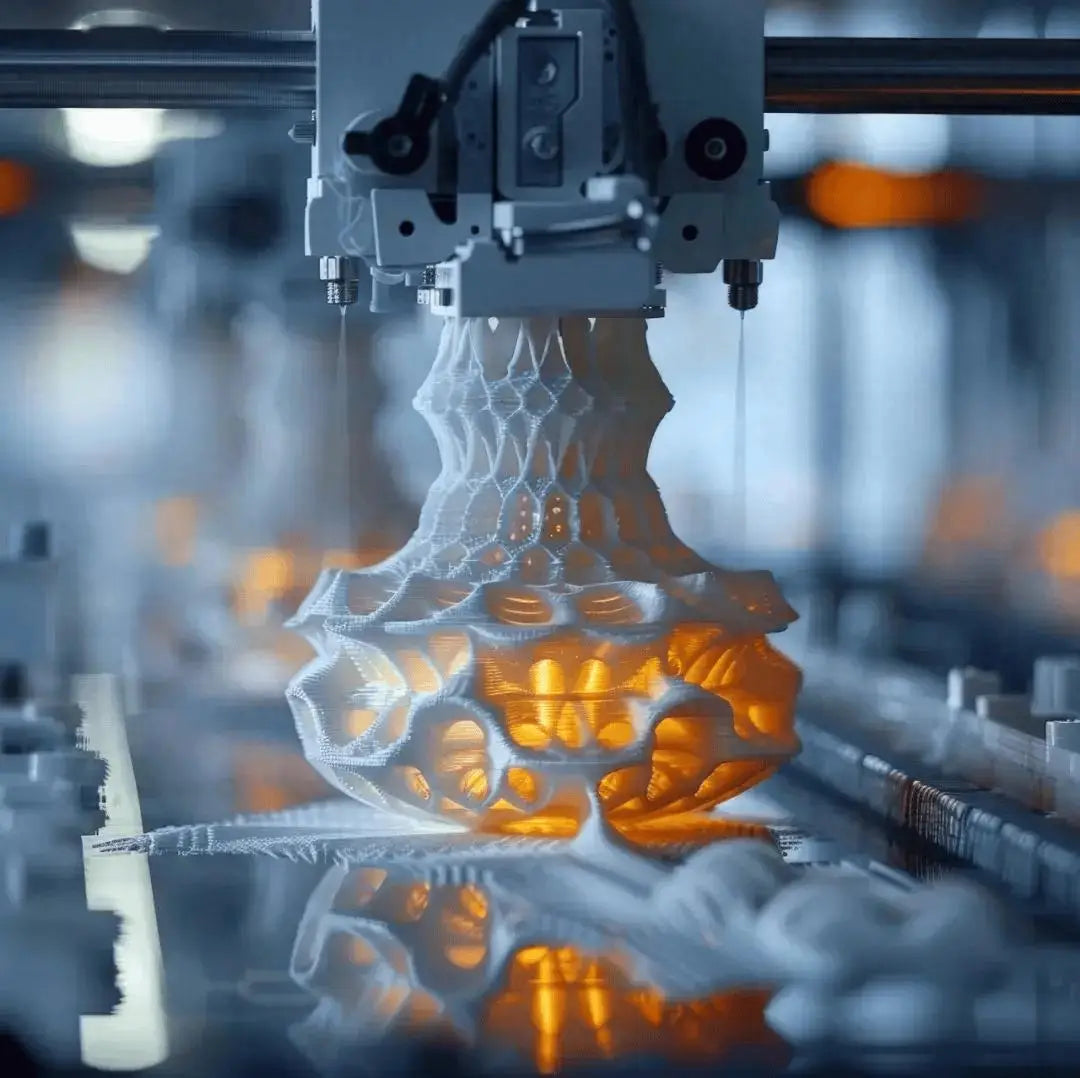

3. SLA/DLP (light-curing) 3D printing materials

Light-curing 3D printers use liquid resins and use ultraviolet light for curing and molding, and the printed objects are more refined.

3.1 Standard resin – high precision, suitable for prototyping

✔ Advantages:

Smooth surface and rich details.

Suitable for printing small precision parts.

❌ Disadvantages:

High brittleness, not suitable for load-bearing parts.

Post-curing is required, and cleaning is required after printing (usually with isopropyl alcohol).

🔹 Application scenarios:

Dental models, jewelry design, miniature figures.

3.2 Engineering resin (high temperature and impact resistance)

✔ Advantages:

Stronger mechanical properties than standard resins.

Can be used for functional parts, such as heat-resistant and impact-resistant parts.

❌ Disadvantages:

Higher price and more complicated post-processing.

🔹 Application scenarios:

Automotive parts, engineering prototypes, industrial applications.

4. Metal 3D printing materials (SLS/SLM)

Metal 3D printers use powder bed fusion technology to sinter or melt metal powders through laser sintering, which is suitable for industrial manufacturing.

4.1 Stainless steel – high strength and corrosion resistance

✔ Applications: aerospace, automotive, medical equipment, tool manufacturing.

4.2 Titanium alloy – lightweight and high strength

✔ Applications: spacecraft parts, medical implants (such as dentures, bone replacements).

5. Key factors in choosing 3D printing materials

When choosing 3D printing materials, you need to consider the following:

Printer compatibility: Make sure your 3D printer supports the material (e.g., filament for FDM, resin for SLA).

Finished product strength: If you need an impact-resistant material, it is recommended to choose ABS or PETG.

Environmental factors: PLA is suitable for indoor use, PETG is suitable for outdoor use, and ABS needs to be used in a closed printer.

Post-processing requirements: Resin prints need to be cleaned, ABS can be polished with acetone, and PETG is easy to polish.

Budget considerations: PLA is cheap, while engineering resins and metal powders are more expensive.

6. Conclusion

Choosing the right 3D printing material is the key to improving print quality and success rate. PLA is suitable for beginners, ABS is suitable for industrial applications, PETG has both toughness and durability, and SLA resins provide high-precision printing. If you need to print more advanced functional parts, you can consider engineering resins, TPU, or metal powders.

I hope this guide can help you find the right 3D printing material and make your 3D printing project more successful! If you have any questions, please leave a message in the comment area! 🚀