3D Printing Technology Development Trends: Innovation, Breakthrough and Future Outlook

Introduction

3D printing technology (also known as additive manufacturing) has made great progress in recent years and is widely used in many industries such as medical, aerospace, automotive manufacturing, and construction. With the advancement of material science, printing speed, and intelligent technology, 3D printing is moving from prototyping to mass production. In 2024, the development trend of 3D printing technology will be more intelligent, efficient, and sustainable, driving the transformation of the global manufacturing industry.

In this article, we will explore the latest trends, industry applications, market growth, and possible future development directions of 3D printing technology.

1. The latest development trends of 3D printing technology

1.1 Faster printing speed and automated production

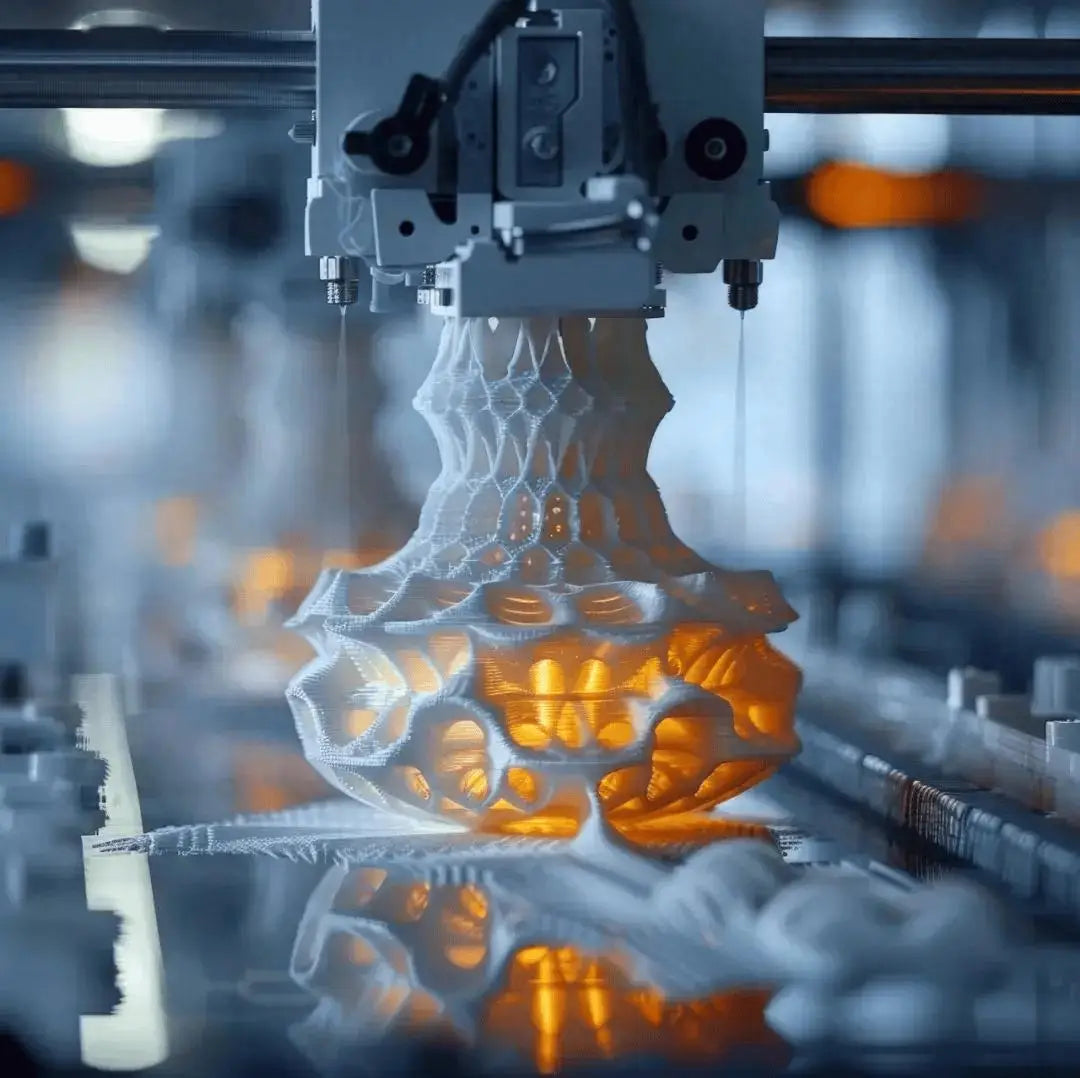

One of the bottlenecks of traditional 3D printing technology is the slow printing speed, which limits its application in mass production. However, with the emergence of high-speed 3D printing technologies, such as continuous liquid interface production (CLIP), selective laser sintering (SLS), and optimization of fused deposition modeling (FDM), the printing speed has been greatly improved. For example, the CLIP technology launched by Carbon 3D can print complex parts in just a few minutes.

In addition, 3D printing factories are adopting automated production lines, combined with robots and artificial intelligence, to achieve unattended continuous manufacturing. This trend helps reduce labor costs, improve production efficiency, and promote the application of 3D printing in large-scale manufacturing.

1.2 Development of high-performance materials

Advances in materials science are key to promoting the development of 3D printing. In 2024, we will see more applications of high-performance materials, including:

High-strength engineering plastics (such as PEEK, Ultem) for aerospace and medical device manufacturing.

Biocompatible materials promote the application of 3D printing in medical and prosthetic manufacturing.

Recyclable and environmentally friendly materials, such as bio-based PLA and recyclable metal powders, are in line with the trend of green manufacturing.

Flexible materials and composite materials can be used in smart wearable devices, sports shoes manufacturing and other fields.

The development of these new materials will further broaden the application scenarios of 3D printing and greatly improve its feasibility in multiple industries.

1.3 3D Printing + Artificial Intelligence (AI)

Artificial intelligence is empowering 3D printing, making it more intelligent and precise. For example, AI algorithms can optimize printing paths, predict possible printing defects, and automatically adjust parameters to increase printing success rates. In addition, machine learning can analyze large-scale production data, improve printer maintenance efficiency, and reduce failure rates.

Some companies have begun to develop AI-driven 3D printing software, such as Autodesk and Siemens NX, to help designers generate optimized structures faster, reduce material waste, and improve product quality.

1.4 Large-scale application of metal 3D printing

Metal 3D printing technology is developing rapidly, especially in the aerospace, automotive, and medical industries. For example, Boeing and Airbus have adopted metal 3D printing technology to produce aircraft parts to reduce weight and improve fuel efficiency.

Currently, mainstream metal 3D printing technologies include:

Selective Laser Melting (SLM)

Electron Beam Melting (EBM)

Powder Bed Fusion (PBF)

As the cost of metal printing decreases and printing accuracy improves, metal 3D printing is expected to enter a wider range of industrial applications in the next few years.

1.5 Sustainability and environmentally friendly 3D printing

With the global focus on sustainable development, the 3D printing industry is moving towards green manufacturing, including:

Use recyclable materials to reduce waste in the production process.

Optimize printing design, reduce material consumption, and improve energy utilization.

Develop environmentally friendly printing technologies, such as low-energy 3D printing and bio-based printing materials.

Currently, some companies are developing fully biodegradable 3D printing materials, which may be used in consumer goods, packaging and medical industries in the future.

2. Industry application prospects of 3D printing

2.1 Aerospace and automotive manufacturing

Use 3D printing to produce lightweight parts and improve fuel efficiency.

Develop more complex aerodynamic structures to improve aircraft performance.

Quickly produce customized automotive parts, such as 3D printed parts in F1 racing cars.

2.2 Medical and bioprinting

3D print prostheses, dental models, implants, and enhance patient experience.

Study 3D printed organs (bioprinting), which is expected to solve the problem of organ shortage in the future.

Personalized drug manufacturing, 3D printed pills can be customized according to patient needs.

2.3 Architecture and Infrastructure

3D printed buildings have become a reality, such as the 3D printed office building in Dubai.

Using concrete 3D printing technology to reduce construction time and cost.

In the future, there may be eco-cities built entirely by 3D printing technology.

2.4 Consumer electronics and personalized manufacturing

3D printed smart wearable devices, such as customized headphones and watch cases.

3D printed jewelry, clothing and footwear to improve personalized consumer experience.

3D printing is used in the gaming industry to create customized character models and accessories.

3. Future Outlook: How will 3D printing change the world?

Popularization: The price of 3D printers has dropped, and more companies and individuals can use the technology.

Fully automatic manufacturing: Unmanned 3D printing factories will become a reality in the future, improving production efficiency.

Nanoscale 3D printing: In the future, there may be technology for printing nanoscale structures for medical micro-implants.

3D printing in space: NASA is studying how to 3D print building materials in space to support future colonization of Mars.

3D printing of food: Scientists are studying 3D printing of artificial meat, desserts and other foods, which may change the food industry.

Conclusion

3D printing technology is undergoing a revolution. Faster printing speeds, stronger materials, smarter AI optimization, and wider industry applications are driving this technology into the stage of large-scale manufacturing. Whether it is medical, aerospace, construction or consumer electronics, 3D printing is creating new possibilities.

With the continuous innovation of technology and the decline in costs, 3D printing will become an important part of the manufacturing industry in the next few years. It is crucial for enterprises to keep up with this trend, and for individual makers and designers, 3D printing is providing them with unlimited creative space.

If you are considering using 3D printing technology, now is the best time - let us witness this transformation of the manufacturing industry together!